Is it time for your older inefficient boiler to be replaced with a high-efficiency condensing boiler? High-efficiency boilers can be over 20% more efficient than existing systems, leading to significant savings. Older boilers may operate at 75% efficiency or below and a replacement system may achieve efficiencies well above 90%.

High efficiency condensing boilers

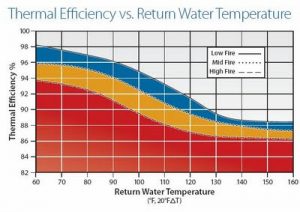

Replacing large antiquated boilers with modern condensing units will bring energy and cost savings, increased occupant comfort and reliability. Older hot water boilers lose a significant amount of energy out the flue. To avoid flue gas condensation, boiler flue-gas temperatures are often kept at 300°F or higher, which also decreases efficiency. Newer condensing boilers achieve higher efficiency through much lower stack exhaust temperatures. Energy efficiency is highest in a condensing boiler when the return water temperature and the firing rate are low. The figure below, from Emerson Swan, shows a direct correlation between return water temperature and boiler efficiency. The cooler the return water is, the higher the thermal efficiency. If the system return water temperature is 80°F or lower, you can achieve very high efficiencies; however, in many older systems the return water temperature is considerably higher, leading to a much lower thermal efficiency.

Modulating boilers

SEDAC frequently recommends replacing an old boiler system with one that modulates. Modulating systems constantly adjust to meet the heat demand. Modulating furnaces and boilers can save energy, utility costs, and increase comfort by maintaining stable temperatures. Space conditioning demand, or the amount of heating or cooling required to maintain interior comfort conditions, varies throughout the year. Engineers design heating and cooling systems to meet the “design conditions” for a specific location. These conditions include a low or high temperature that the local temperatures are not expected to drop below or exceed, 99% of the time. These conditions establish the maximum amount of heat that will be required during the heating season, and the maximum amount of cooling that will be required during the cooling season.

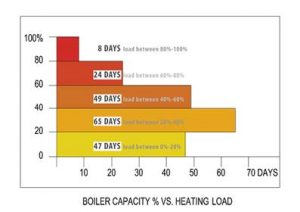

The graph to the right shows what the demand on the boiler will be for a location in Springfield, IL with a 239-day heating season. Notice that the boiler needs to operate at peak load (between 80-100%) for only 15 days of the heating season. These are days when outside temperature is 12°F or lower. The heating system needs to be able to supply heat for those rare extremely cold days. For the rest of the heating season, the heating plant needs to provide significantly less heat.

It is during these milder periods that it is desirable to have a heating plant that can modulate the amount of heat provided. Many older systems, where the heating system cannot modulate, satisfy low heating demand by simply cycling the heating system on and off. Cycling of heating systems can lead to increased fuel consumption and fluctuating interior temperatures which can compromise occupant comfort. Modulating systems have the ability to constantly adjust input to meet a specific output demand. Modulating furnaces and boilers can save energy, utility costs, and increase comfort by maintaining stable temperatures.

When should you replace your boiler?Replacing boilers can be expensive and complicated. For many people, maintaining or retrofitting an old boiler will be preferable until the boiler fails or it can be shown that it’s financially beneficial to replace it. SEDAC can help you decide the best strategy by assisting you in answering the following questions:

- What is the current cost of operation of your existing boiler, including maintenance and fuel usage?

- Can the existing boiler be made more efficient and how much will it cost?

- What are the consequences of a failed boiler?

- What are the anticipated savings of a new high efficiency boiler?

- What are your economic criteria?

- Are there incentive programs to help offset the cost of replacing your boiler?

Boiler maintenance

A boiler will last longer and be more efficient if it is maintained. A poorly maintained boiler may fail in two decades while a well maintained boiler can last a very long time. For example, Rockford schools have 75-year-old boilers that are maintained annually. They continue to function and provide steam, albeit at a low efficiency.

Boiler tune-ups require a licensed technician to examine the boiler, perform tests and make sure safety systems are functioning properly. These tests ensure the boiler is working to manufacturer specifications and EPA emission standards. For boilers that are not serviced annually, tune-ups frequently result in a 1.6% efficiency gain in the operation of the boiler, resulting in payback periods in most cases of less than six months.

How often the boiler is serviced will depend on the boiler’s age and condition. Many new boilers have sophisticated controls that monitor operation and provide fault codes if there’s a problem. These boilers may not require annual check-ups for the first few years, but an annual check-up is still recommended.

Boiler retrofits

It is also possible to retrofit older boilers with a stack economizer or boiler flue condenser to capture a portion of the waste heat and transfer it to the boiler feed-water, cold makeup water, hot water return, a hot water storage tank, condensate tank, process water, or potable water. The difference between an economizer and condenser is that economizers are primarily used to heat a smaller volume of water to a high temperature for boiler feed water, and condenser units heat a larger volume of water to a lower temperature. Economizers may also be used to preheat combustion air.

For more information, see:

https://energy.gov/energysaver/furnaces-and-boilers

http://www.greenbuildingadvisor.com/blogs/dept/guest-blogs/sizing-modulating-condensing-boiler