The Field Museum is a distinctive landmark along Chicago’s lakefront museum campus. At 1.2 million square feet of floor space, the museum’s size equates roughly to 21 football fields—an apt comparison when considering the Chicago Bears play across the street. The Field Museum’s facilities and holdings rank it as one of the premier natural history museums in the world.

The Field Museum offers exhibit areas for visitors— students, international tourists, and other guests—as well as lab areas where curatorial and scientific staff conduct research. Much of the actual square footage is dedicated to storage and preservation.

Even though the Field Museum has an impressive history of energy conservation, the energy required to service >1 million square feet of building space is quite significant. The building, which is nearing its 100th birthday, has undergone many changes to its complex mechanical and lighting systems. In 2002 the central steam boilers and chillers were replaced.

As a result of earlier improvements, the Field Museum operates a thermal energy storage system that creates ice during the night when lower electricity costs are in effect. The ice is used for cooling during the day, a practice that allows chillers to remain off when electricity is more expensive and helps to reduce the stress on the electric grid. The Smart Energy Design Assistance Center (SEDAC) was tasked to perform an in-depth analysis of energy usage at the Field Museum in 2013.

"It was exciting to work on a building of this size since the energy-saving potential is tremendous. The Field Museum was already performing well. The challenge was identifying which upgrades to building operations would best meet the Field Museum's goals." --Greg Swiss, SEDAC Building Energy Specialist

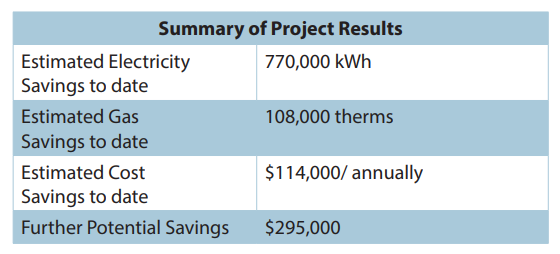

SEDAC recommended implementation of 15 energy saving measures ranging from steam system upgrades to ventilation system modifications, lighting retrofits, scheduling adjustments, and power management. Sample measures recommended for implementation:

SEDAC recommended implementation of 15 energy saving measures ranging from steam system upgrades to ventilation system modifications, lighting retrofits, scheduling adjustments, and power management. Sample measures recommended for implementation:

- Upgrades to approximately 455 kW will generate some $175,000 in annual savings.

- Two measures addressed low-cost adjustments to the Museum’s air handlers, changes that annually save $14,400 and $28,000.

The Field Museum has already implemented several SEDAC recommendations, including:

- Retrofitting old steam traps to improve steam system efficiency

- Installing demand control ventilation to align ventilation levels with occupancy

- Replacing outdated lighting with efficient LED lamps

- Adjusting vending machine scheduling to curb machine energy consumption

- Initiating computer power management to cut power consumption during inactive periods

- Completing an automatic chilled water supply reset to ensure efficient chiller operation

- Closing outdoor air dampers during unoccupied times to reduce heating and cooling energy usage

"SEDAC has been a vital resource in helping us identify ways to save energy and reduce our utility costs, as well as effectively plan our five and twenty year capital improvement work plan." --J.W. Croft, Executive Vice President for the Field Museum